Tank Management System

FUMANS Tank Management System sustains the management and control of fuel tank refuelling in stations, construction sites and storage facilities.

The system prepares instant data analysis on fuel type, refuelling levels and measurements, fuel checkout levels and management, inventory, levels (Lt/cm), temperature, alarms, real-time hour/date range detailed reporting, measurement tables etc. and pairs this data with the information received from the pump automation system.

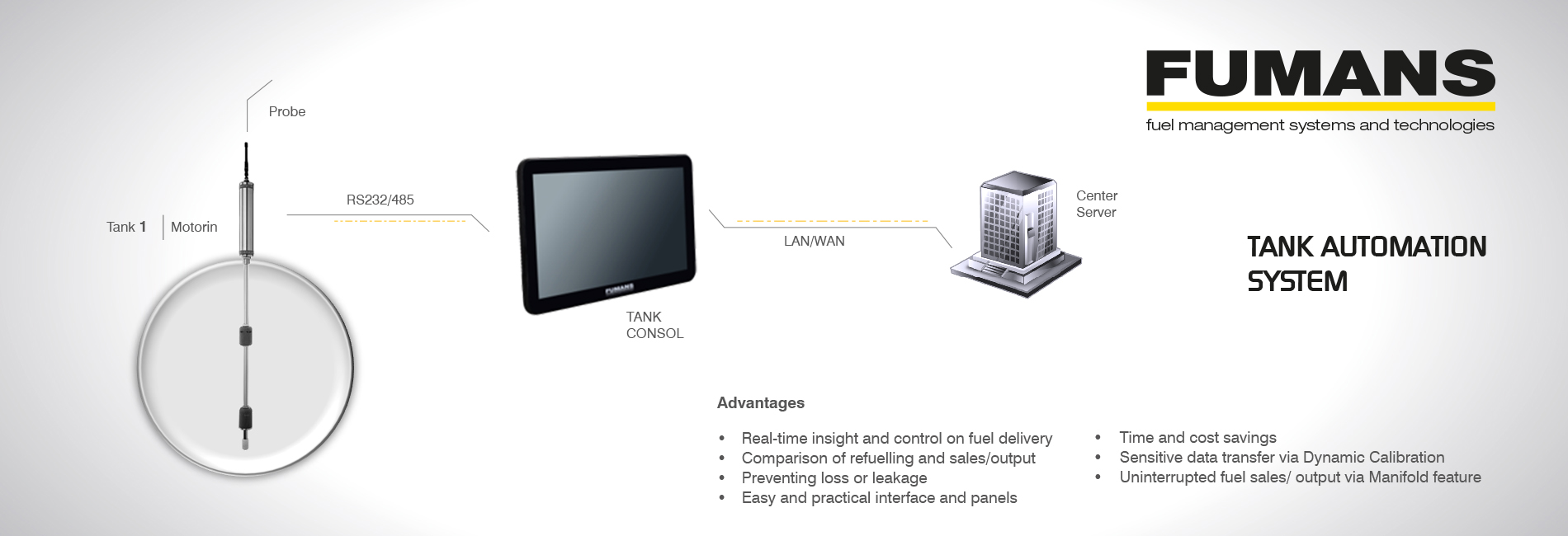

The Tank Management System is integrated into the pump automation system however, if required, it can be used on its own by attaching a Tank Console Device. The Tank Management System communicates with all cable, wireless or radar level measuring devices (Probe) within the country and abroad.

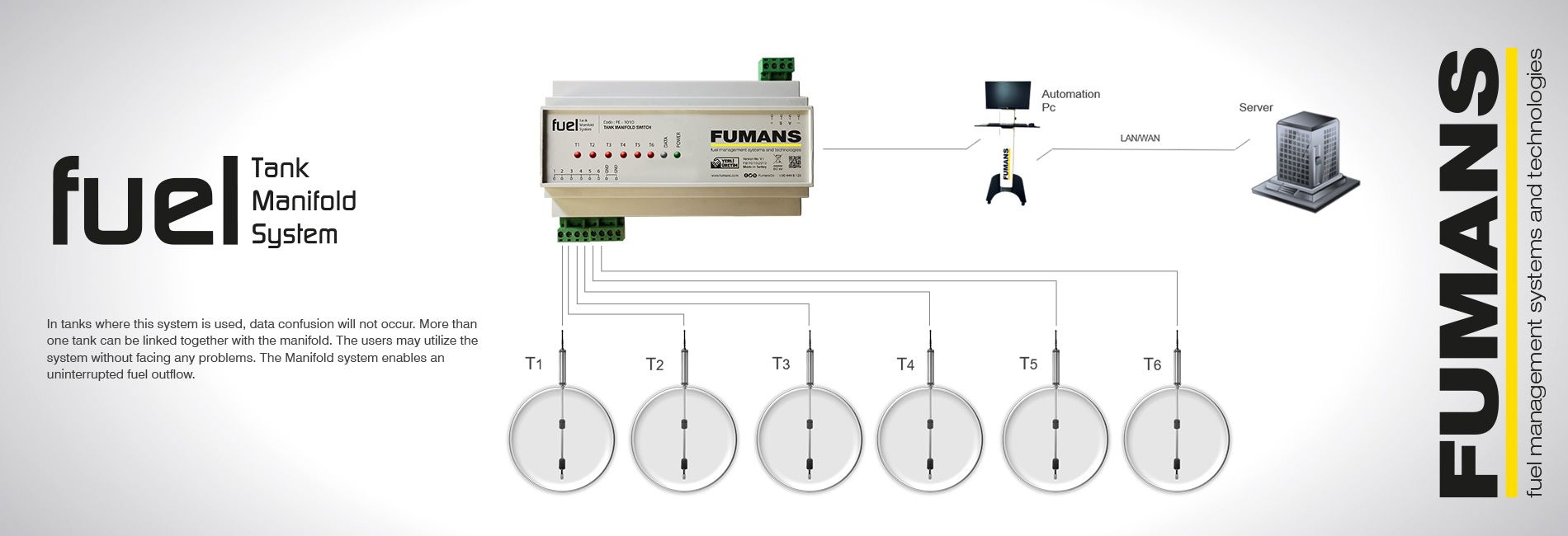

Tank Manifold System (Fuel Tank Manifold Switch)

Tank Management Systems use a manual or automatic manifold system.

In tanks where this system is used, data confusion will not occur. More than one tank can be linked together with the manifold. The users may utilize the system without facing any problems. The Manifold system enables an uninterrupted fuel outflow.

Dynamic Calibration

The Tank Management System Software contains a Dynamic Calibration Software.

In the event that the existing tanks do not calibrate, the system automatically produces a sensitive Dynamic Calibration when there are fuel sales from the pumps in stations or at the construction sites. This procedure eliminates the high cost and long duration of additional calibration operation while conserving time and resources.

Online and offline capabilities

- PC and industrial based automation options

- Unlimited refuelling delivery

- Shift system

- Integration to ERP Systems

- Detailed Reporting

- Fuel Fluctuation Data Filer

- Fuel Refuelling Tracking

- Fuel Stock Management

- Fuel input/output management and control

- Manifold system

- Dynamic Calibration

Data concerning in-tank movements, instant inventory information, tank number, capacity, fuel type, fuel quantity (Lt / cm), fuel temperature, water level (Lt / cm), date, time, personnel information, is instantly registered by connecting to the level measurement devices (Probe) that are located in underground or over-ground fuel tanks in stations, construction sites and storage facilities.

Probes and equipment, which are determined after a careful examination of the tanks’ capacity, status, as well as the fuel type inside them, are then mounted either by cable or wirelessly.

It transfers real time data to the head office where the Central Fuel Management System is installed.

The system works online and offline.

The tank screens are monitored online from the Central Fuel Management System.

Advantages

- Real-time insight and control on fuel delivery

- Comparison of refuelling and sales/output

- Preventing loss or leakage

- Easy and practical interface and panels

- Time and cost savings

- Sensitive data transfer via Dynamic Calibration

- Uninterrupted fuel sales / output via Manifold feature